Sturrus Technology Center

Sturrus Technology Center

Muskegon, MI 49440

Hours of Operation

Mon-Thu

8:00 am - 5:30 pm

Fri

8:00 am - 12:00 pm

Phone

Campus Email:

Office Location

Main Desk

STC Applied Technology Programs

View a video of MCC programs located at the STC or learn more about them below.

CAD

With work stations connected to 3-D printers, the CAD program introduces you to design, the starting point of everything that is manufactured today. Demand for CAD positions is expected to rise 2.5% through 2028, and the median wage is $21-33/hour.

Electronics/Automation

With a suite of electric panels and ten robots, MCC is implementing a revamped program focusing on automation. Starting with the basics about electric current, through programmable logic controllers (PLC) and robot programming, you will be

ready for Industry 4.0. Demand for electricians is expected to rise 5.5% through 2028, and the median wage is $22-37/hour.

Engineering

MCC offers both a Mechanical Engineering Pathway degree and an Associate in Applied Science in Manufacturing Engineering Technology degree. Demand for industrial engineering technician positions is expected to rise 8.6% through 2028, and the median wage is $35-52 hour.

Machining

The STC has MCC’s first 5-axis computer numerical control (CNC) mill. In addition, many CNC turning centers and CNC vertical machining centers bring this program to the next level. Demand for machinists is expected to rise 3.1% through 2028, and the median wage is $16-26/hour.

Materials

Because cast metals and the accompanying skills of material testing are a bedrock of Muskegon industry, there is a foundry and a testing lab at the STC our lab is equipped with tensile and hardness testers, along with a spectrometer. Demand for Mechanical Engineering technicians is expected to rise 2.4% through 2028, and the median wage

is $21-34/hour.

Welding

The Welding lab has 17 state of the art booths, along with fabrication equipment and welding robots. Demand for welders is expected to rise .2% through 2028, and the median wage is $16-23/hour.

Tours

To arrange a private tour of the STC, please contact:

Associate Dean of Workforce & Talent Development

Sturrus Technology Center

Phone: 231-777-0456

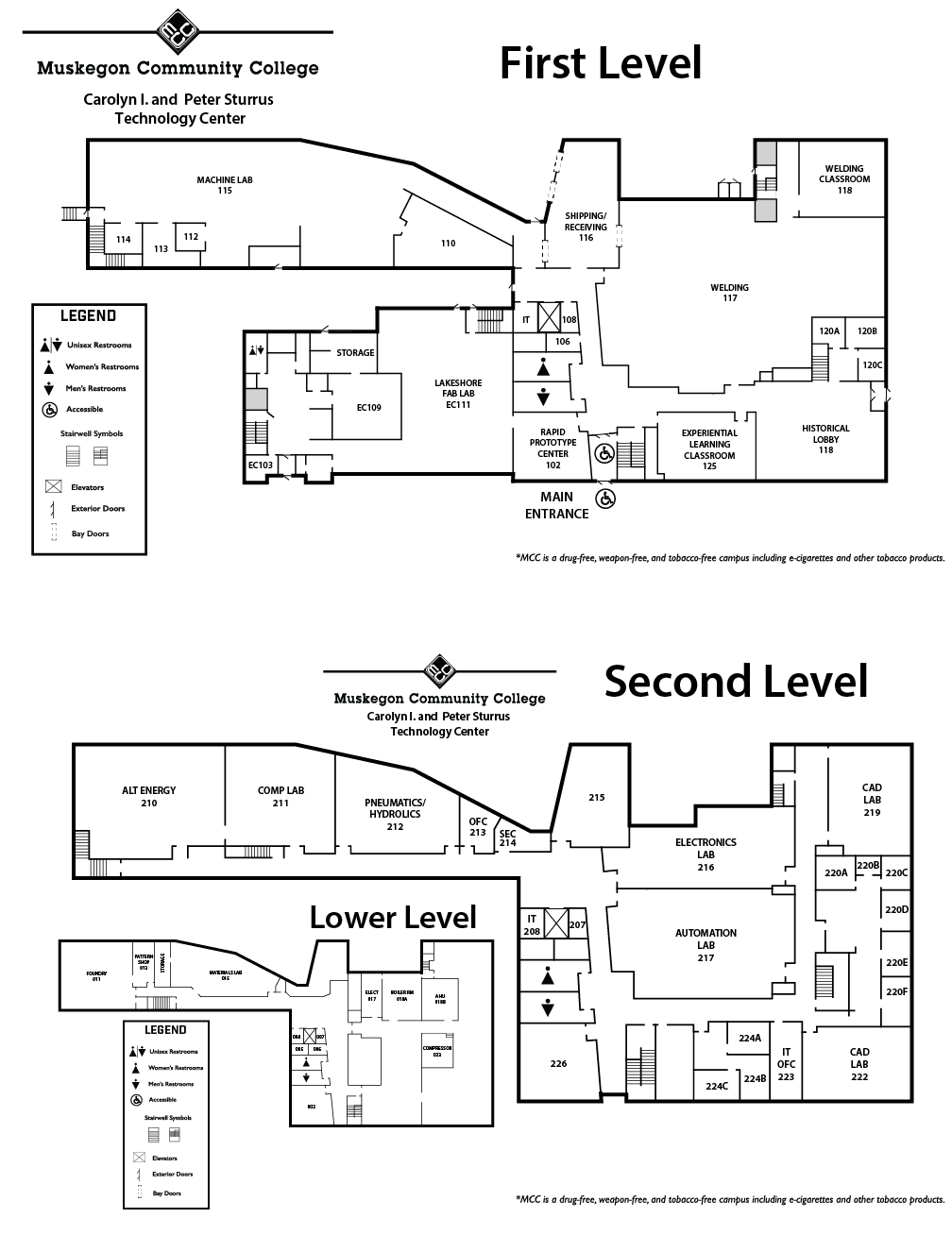

STC Labs and Classrooms

Room 011 – CWC Textron Foundry Lab (2,495 sq. ft.)

With an all-new Sinto Sandmold foundry system and accompanying existing Inductotherm furnace, the CWC Textron Foundry Lab will prepare the next generation of foundry workers.

Room 013 – James and Florence Jackson Pattern Shop (497 sq. ft.) and Finishing Room (286 sq. ft.)

Adjoining the CWC Textron Foundry Lab, the Pattern Shop, which is sponsored by Stephen and Debra Jackson in memory of James and Florence Jackson, has equipment to grind and finish parts and molds created for a foundry. The Finishing Room is sponsored by Susan Jackson in memory of James and Florence Jackson.

Room 015 – Material Testing Lab (2,292 sq. ft.)

The science of testing materials for quality purposes to meet specifications, metallurgy is an important manufacturing function. This lab boasts a new spectrometer, along with hardness and tensile testers, which will expose students to key tools in this important field.

Room 110 – Machine Technology Classroom (940 sq. ft.)

Adjacent to the Machine Technology Lab, this classroom is the meeting place for each class as it gets underway and allows instructors to discuss the main objectives and concepts for the class before students head in to Machine Technology Lab to work on their projects.

Room 115 – Northern Machine Tool Co. Machine Technology Lab (5,212 sq. ft.)

Home to manual and CNC machines for metal working, the focus here is to increase CNC machines and new equipment, such as new Haas mills and lathes.

Room 112 – Arconic Foundation Metrology Lab (124 sq. ft.)

This room houses coordinate-measuring machine (CMM) and other measuring and quality tools for machining students to practice quality control processes on finished parts.

Room 117 – Welding Technology Lab (6,886 sq. ft.)

This lab houses 16 new welding booths, complete with new welders and a gas manifold system, along with a large fabrication area that includes a new shear, hem saw, punch press, and welding robotic equipment.

Room 118 – Welding Classroom (988 sq. ft.)

Adjoining the Welding Technology Lab, this classroom can accommodate 16 students and has Smart Board capabilities.

Room 120 – Student Services Offices

This office complex, which is used by the MCC Student Services staff, includes the Larry Wright Waiting Room and the Neil Sanders Office, as well as two others.

Room 122 – Student Center (2,074 sq. ft.)

The former Muskegon Chronicle lobby, this beautiful wood-paneled room has been restored to its original splendor. Containing multi-purpose furniture, the facility will primarily be used as a student study area but can accommodate public events.

Dr. Dale and Connie Nesbary Student Lounge

The rear stairwell leads to the Dr. Dale and Connie Nesbary Student Lounge, on the second floor. while the front stairwell leads to the Dr. Alan Steinman Student Lounge.

Dr. Alan Steinman Student Lounge

The front stairwell leads to the Dr. Alan Steinman Student Lounge on the second floor.

Room 210 – Alternative Energy Classroom (2,408 sq. ft.)

This classroom/lab hosts MCCs Alternative and Renewable Energy program. It includes solar electric, solar hot water, and wind turbines. There is an indoor residential roof for solar array installation and lab space for wind turbine troubleshooting and analysis. This room is also used for Residential Electricity. Students install and wire switches, lighting, and panels for hands-on training.

Room 211 – Robert Slager Applied Technology Lab (1,658 sq. ft.)

This computer lab has 24 student stations for use with Machining, Quality Assurance, CAD, Technical Math and other classes. There are 16 Haas CNC programming simulators that interface with the Machine Technology Lab equipment to allow practice coding CNC machined parts.

Room 212 – Electronics Lab (1,505 sq. ft.)

This lab has 20 computer stations used for simulation and design software for electronics classes. It is also the hands-on training lab for the BioMed Electronics classes and includes pumps, EKGs, defibrillators, ventilators, and a variety of modern medical equipment common to hospitals and clinics.

Room 215 –Classroom (961 sq. ft.)

A general purpose classroom for general education requirements associated with Applied Technology degrees.

Room 216 – Electricity Lab (1,905 sq. ft.)

This lab has components and diagnostic instruments for understanding analog and digital electrical circuits, from basic topics to advanced.

Room 217 – Arconic Foundation Automation Lab (2,732 sq. ft.)

This lab includes industrial robots, electrical panels, PLCs, hydraulic, and pneumatic equipment for hands-on electric training. Programming, communications, sensors, conveyors, and temperature chambers are used to explore the concepts of industrial controls and automation.

Room 219 – CAD Computer Lab (1,302 sq. ft.)

This lab contains 20 student CAD stations – all with dual monitors, solid state drives, and installed with the latest in CAD software.

Room 220 – Applied Technology Department Offices (842 sq. ft.)

This complex of offices serving the Applied Technology Department chair and faculty members, includes the Arild and Margaret Nielsen Reception Area and the Comerica Foundation Storage Room.

Room 222 – Arconic Foundation CAD Computer Lab (1,143 sq. ft.)

This lab, which is sponsored by the Arconic Foundation, contains 20 CAD student stations, all with dual monitors, solid state drives, and installed with the latest in CAD software.

Room 223 – Arconic Foundation Additive Manufacturing Lab (336 sq. ft.)

This lab houses a new large format plotter, a 3D printer, and a new 3D scanner.

Room 225 – Canteen Vending Student Lounge (350 sq. ft.)

Students can access this room anytime they are in the Sturrus Technology Center to use vending machines or microwave ovens to heat their meals.

Room 226 – DTE Energy Foundation Classroom (907 sq. ft.)

A general purpose classroom sponsored by the DTE Energy Foundation, this room is used for general education requirements that are part of Applied Technology degrees.

Center for Experiential Learning

Room 125 – Dr. Donald and Nancy Crandall Experiential Learning Lab (1,030 sq. ft.)

Part of the Center for Experiential Learning, this lab includes innovative group work technology. Combined with its central downtown location amidst a variety of historic buildings, the facility will bring class work to life. This classroom is often used for Studio M, a interactive capstone class of the graphic design program.

Rooks|Sarnicola Entrepreneur Institute

Visitors enter the Rooks|Sarnicola Entrepreneur Institute from its W. Clay Ave. entrance across from Hackley Park. They will pass through Helstrom Vestibule and into the Essex/Port City Group Lobby.

Room EC 111 – Lakeshore Fabrication (Fab) Lab (3,263 sq. ft.)

Beginning Spring 2018, the Lakeshore Fab Lab, sponsored by the Grand Haven Area Community Foundation and the Community Foundation for Muskegon County, will offer a dynamic environment for entrepreneurs of all ages to bring their ideas to life. CAD stations, 3D printers, robotics, laser etching, production machining, and much more will be available on a membership and materials basis. Connected to the Global Fab Lab network, it will be possible to tap into ideas and help worldwide. The Fab Lab includes the Fremont Area Community Foundation Makerspace Storage Area.

Room 102 – Richard and Ann Kraft Rapid Prototype Center (899 sq. ft.)

Sponsored by Richard and Ann Kraft, this room is part of the Lakeshore Fab Lab and open to use by Fab Lab members. The room contains 12 CAD stations, Stratasys high and midrange 3D printers, and a 3D scanner. In addition to use by Fab Lab members, this room is used for trainings held by the Lakeshore Fab Lab.

Sturrus Technology Center Namesakes

On Sept. 20, 2017, Muskegon Community College’s downtown center officially became the Carolyn I. and Peter Sturrus Technology Center after the local couple donated a record $1.5 million gift to the College to name the facility. The Sturrus’ donation represents the largest – by more than a million dollars – individual gift to MCC.

“I am doing this for the love of Muskegon and the love of Muskegon Community College,” explained Peter Sturrus, who was the longtime president of Shape Corp. in Grand Haven, MI, before passing away in 2023, and once took classes at MCC while beginning his career as a tool-and-die maker. His classes transferred to Aquinas College, where he received his business degree.

“The main reason I did this was to honor my wife, Carolyn Iversen Sturrus,” he continued. “She served as Assistant to the President of MCC for over 30 years, beginning right out of high school.” Click here to read the complete story.

The STC cost $16.125 million to complete the renovations in 2017, and MCC received an additional $3.7 million as an equipment grant from the state of Michigan to outfit the building, bringing the total project cost to $19.8 million.

Bus Routes from Main Campus

Click here to view the Muskegon Area Transit System (MATS) bus route between the main campus and the Sturrus Technology Center – Routes 11

Looking to host an event at the Sturrus Technology Center?

The Sturrus Technology Center can host your event. For more information click here.

Naming Opportunities

The MCC Carolyn I. and Peter Sturrus Technology Center offers corporations and individual donors many opportunities to have a classroom, laboratory or the building itself named in their honor. For more information on the Carolyn I. and Peter Sturrus Technology Center naming opportunities, contact: